Description

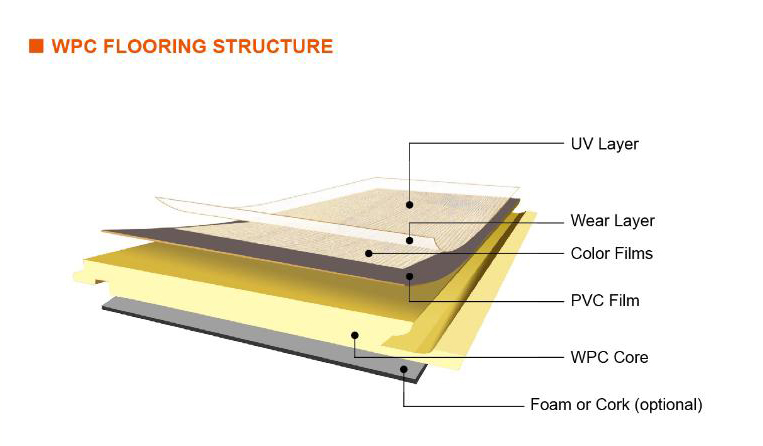

STRUCTURE PICTURE:

Herringbone on wpc flooring,imitaion real wood visual effect, rich installation methods to meet user’s diverse needs.

Realistic-looking grout groove system for click-profiled wpc planks and tiles, mimicking ceramic tile joint, it has perfect perfomance and visual effect.

Special UV technology, anti-bacterial anti-stain and anti to micro scrathes, super surface protect technology for wpc floor.

AVAILABLE SIZES INFORMATION:

Thickness: 4mm+1.5mm LVT, 5mm+1.5mm LVT, 9mm+1.5mm LVT

Length and width: 1218x228mm, 1218x180mm, 1218x148mm, 1545x228mm, 1545x180mm 1545x148mm,

600x300mm, 469x469mm

INSTALLATION: CLICK LOCK

Why Choose Us

Our capacity:

-2 WPC Substrate production line

- 1 LVT Bottom Material production line

-12 press machine line

- 20+ testing equipment

- Average capacity per month is 150-200x20’containers.

Guarantee:

-15years for residential,

-10years for commercial

Certificate:

ISO9001, ISO14001, SGS, INTERTEK, CQC, CE, FLOOR SCORE

Advantage:

Much better dimensional stability

Stronger click system

Phthalate free

Natural comfort

100% water proof

Resilient

Durable

Upscale look

Low maintenance

Environmentally friendly

Easy installation with click system

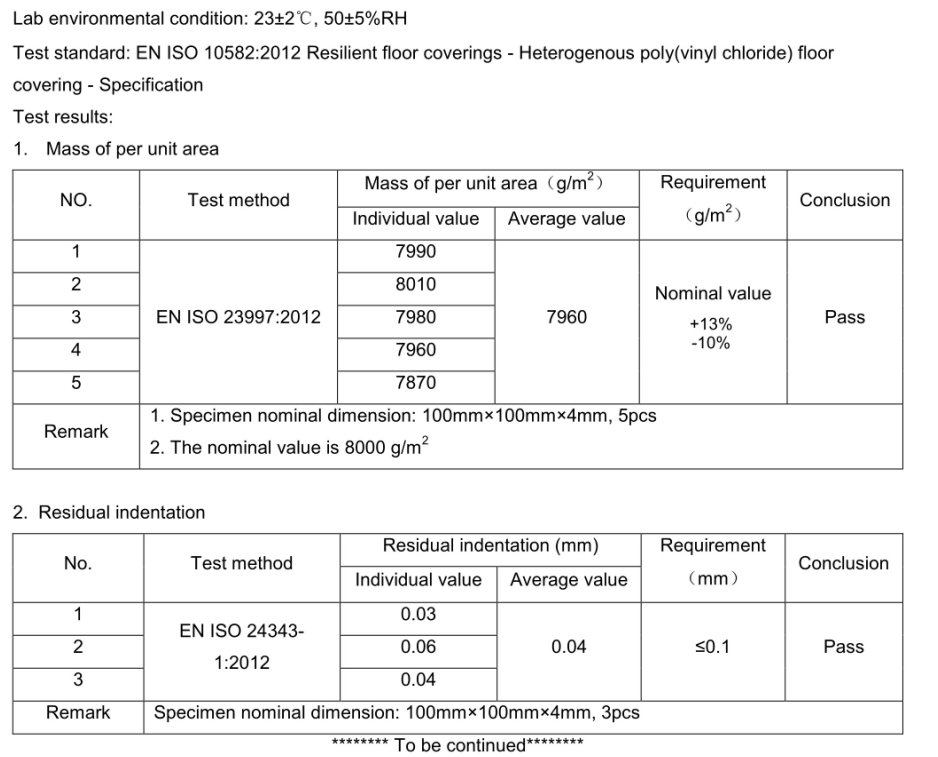

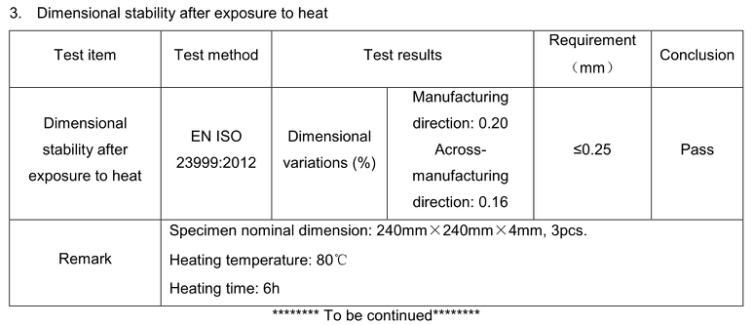

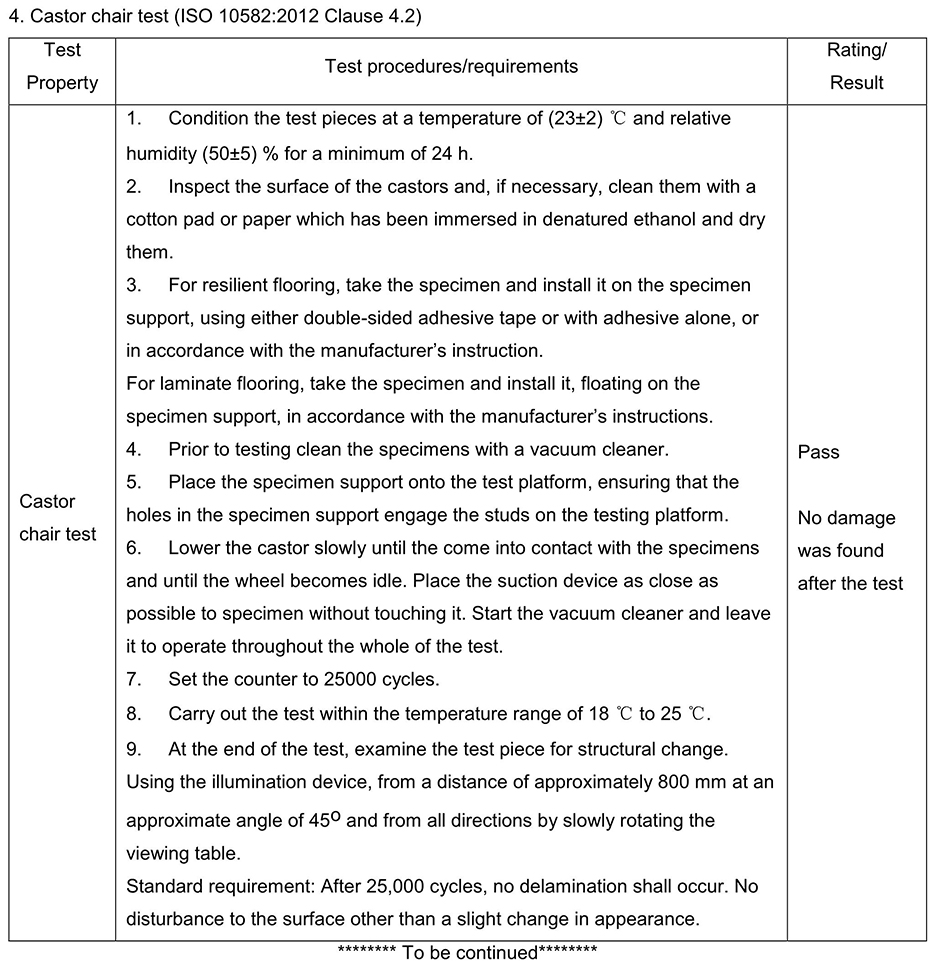

Technical data

| Technical Data Sheet | ||||

| GENERAL DATA | METHOD | Testing method | RESULTS | |

| Dimensional stability to Heat | EN434 | (80 C, 24Hrs) | ≤0.08% | |

| Curling after Exposure to Heat | EN434 | (80 C, 24Hrs) | ≤1.2mm | |

| Wear resistance | EN660-2 | ≤0.015g | ||

| Peel resistance | EN431 | Length direction/Machine direction | 0.13kg/mm | |

| Residual Indentation After Static Loading | EN434 | ≤0.1mm | ||

| Flexibility | EN435 | No damage | ||

| Formaldehyde emission | EN717-1 | Not detected | ||

| Light fastness | EN ISO 105 B02 | Blue reference | Class 6 | |

| Impact insulation class | ASTM E989-21 | IIC | 51dB | |

| Effect of a caster chair | EN425 | ppm | PASS | |

| Reaction to fire | EN717-1 | Class | Class Bf1-s1 | |

| Slip resistance | EN13893 | Class | class DS | |

| Determination of migration of heavy metals | EN717-1 | Not detected | ||