Description

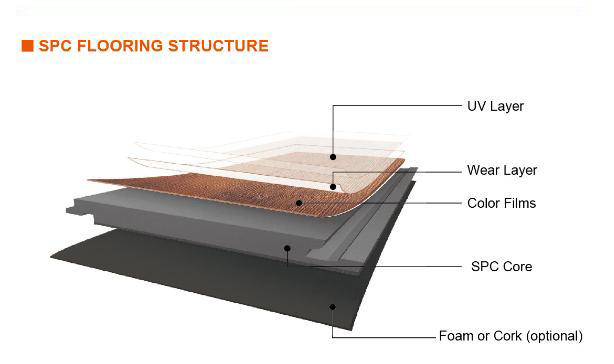

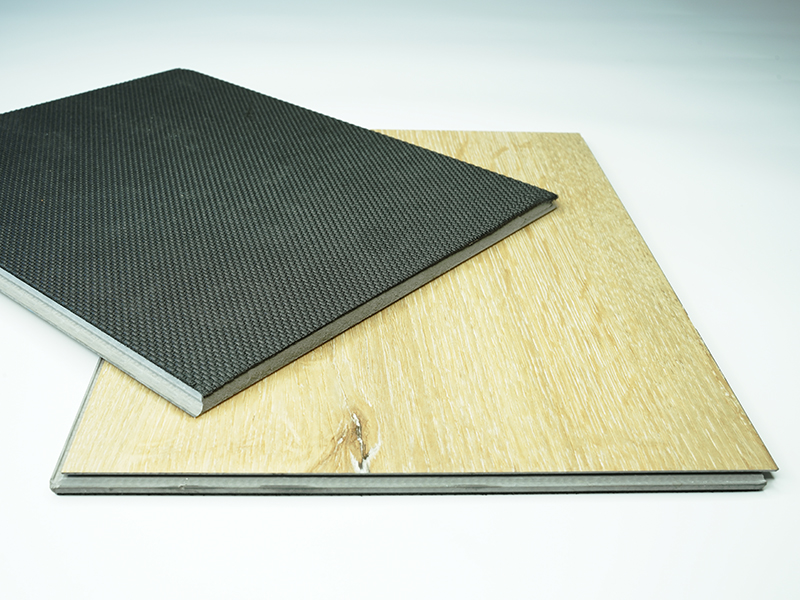

SPC flooring is one kind of waterproof SPC vinyl plank flooring with click system, it is formaldehyde free flooring, much better dimensional stability, environmental protection, easy maintenance and easy installation.SPC rigid core flooring is suitable for all world indoor installation

L-SPC Technology: Lighter 20% than traditional SPC, loading 20% more than in one container, in that case, saving 20% ocean freight cost and inland freight cost. Shortening the installation time because of easy handling and easy installing, thus reducing the labor cost.

On line EIR surface treatment, saving labor cost than hot pressed EIR technology, it has high cost-effective. All patterns and colors are carefully selected, and most patterns and colors are exclusively developed by our company.

Art parquet Hot pressed EIR Technology, perfect EIR surface is produced by our high skilled hot pressing technology. Simulated solid wood parquet pattern brings a very decorate art effect.

Herringbone on SPC floor and laminate floor, Imitation real wood visual effect, rich installation methods to meet user’s diverse needs.

Grout groove technology: realistic-looking grout groove system for click-profiled WPC, SPC and L-SPC planks and tiles. Popular sizes: 610x610mm, 900x450mm, 610x305mm.

Application

AVAILABLE SIZES INFORMATION:

Thickness: 4mm, 4.5mm,5mm, 6mm,8mm.

Length and width: 1218x228mm, 1218x180mm, 1218x148mm, 1545x228mm, 1545x180mm 1545x148mm, 610x610mm, 600x300mm, 900x450mm, 457x457mm, 150x750mm, 150x600mm

Wear layer: 0.2mm-0.5mm

INSTALLATION: CLICK LOCK

APPLICATION SCENARIO:

Education use: school, training center, and nursery school etc.

Medical system: hospital, laboratory and sanatorium etc.

Commercial use: Hotel, restaurant, shop, office, and meeting room.

Home use: Living room, kitchen, and study room etc.

HEALTHY

Using virgin materials, passing the international testing, truly achieve the effects of no formaldehyde, no heavy metals , no odor and antibacterial.

DURABLE:

Wear resistance, scratch resistance, stain resistance

SAFETY:

Slip resistant, fire resistant and insect proof

CUSTOM –PRODUCT:

Product size, décor color, product structure, surface embossing, core color, edge treatment, the gloss degree and function of UV coating can be customized.

Technical data

Issue Date: 2022-01-26 Intertek Report No. 220110011SHF-001

Test Items, Method and Results:

ASTM F3261-20 Standard Specification for Resilient Flooring in Modular Format with Rigid Polymeric Core

Physical Requirements:

| Characteristics | Test requirements | Test Method | Verdict |

| Residual indentation | Average ≤ 0.18mm | ASTM F1914-18 | Pass |

| Dimensional stability | Residential, (avg, max) ≤0.25% Commercial, (max) ≤0.2% |

ASTM F2199-20(70℃, 6h) | Pass |

| Curl | ≤0.080in | Pass | |

| Resistance to heat | (avg, max) ΔE* ≤ 8 | ASTM F1514-19 | Pass |

Note:

1. Test items selscted by applicant.

2. Detailed test results see page 5-7.

Page 4 of 13

Test Items, Method and Results:

Test Item: Residual indentation

Test Method: ASTM F3261-20 section 8.1 and ASTM F1914-18

Conditioning: Condition the test specimens at (23 ± 2)°C and (50 ± 5)% relative humidity for at least 24h

Test Condition:

Indenter: Steel cylindrical foot

Indenter diameter: 6.35 mm

Total load applied: 34 kg

Indentation time: 15 min

Recovery time: 60 min

Test Result:

| Residual Indentation | Result (mm) |

| Specimen 1 | 0.01 |

| Specimen 2 | 0.01 |

| Specimen 3 | 0.00 |

| Average value | 0.01 |

| Max. value | 0.01 |

Issue Date: 2022-01-26 Intertek Report No. 220110011SHF-001

Test Items, Method and Results:

Test Item: Dimensional stability and curling

Test Method: ASTM F3261-20 section 8.3 and ASTM F2199-20

Conditioning:

Temperature: 23 °C

Relative humidity: 50 %

Duration: 24 h

Measure the initial length and curling

Test Condition:

Temperature: 70 °C

Duration: 6 h

Reconditioning:

Temperature: 23 °C

Relative humidity: 50 %

Duration: 24 h

Measure the final length and curling

Test Result:

| Specimen | Dimensional stability (%) Length direction/Machine direction Width direction/Across machine direction |

Curling (in) | |

| 1 | -0.01 | 0.01 | 0.040 |

| 2 | 0.00 | 0.01 | 0.025 |

| 3 | -0.01 | 0.00 | 0.030 |

| Average | -0.01 | 0.01 | 0.032 |

| Max. | -0.01 | 0.01 | 0.040 |

Test Item: Resistance to heat

Test Method: ASTM F3261-20 section 8.5 and ASTM F1514-19

Conditioning: Condition the test specimens at (23 ± 2)°C and (50 ± 5)% relative humidity for at least 24h

Test Condition:

Temperature: 70 °C

Exposure time: 7 days

Spectrophotometer: Under D65 standard light source, 10° observer

Test Result:

| Specimen | ΔE* | Average ΔE* |

| 1 | 0.52 | 0.71 |

| 2 | 0.63 | |

| 3 | 0.98 |

Test Photo:

After exposure

Why Choose Us

Our capacity:

- 3 profiling machine

- 10 extrusion machine

- 20+ testing equipment

- Average capacity per month is 150-200x20’containers.

Guarantee:

-15years for residential,

-10years for commercial

Certificate:

ISO9001, ISO14001, SGS, INTERTEK, CQC, CE, FLOOR SCORE